Injoy our varues choice on preparing your weare house display

Pallet Rack

Pallet racks are the most common type of storage racks. These systems are equally used in small warehouses and large logistics centers, being the most popular because of its simplicity. Pallet racking provides direct access to all units, that are stored on pallets of all types. These constructions can be installed in one or two lines with the required number of layers. Pallet Racking is a dismountable system that consists of following elements: frames, beams and horizontal inter-frame connections. Tiered storage allows maximum use of valuable warehouse space in height, increasing its capacity to 50%. Unlike other rack systems, pallet racks are characterized by lower investment and operating costs. specification of pallet racking provides storage solutions of required loads and heights; high reliability, rigidity and stability against swinging; individually designed elements enable any storage solutions; protective elements that are tested and proven in extreme conditions;

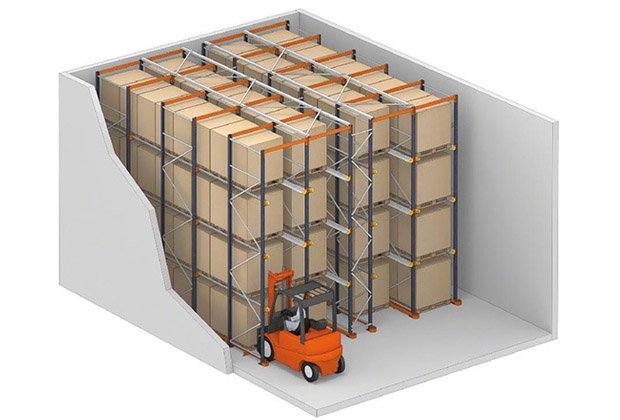

Drive-in Drive-thru

Drive-In Racks are the ideal equipment for storage of large amounts of the same products or long shelf life and low turnover products. This type of shelving is often used in low-temperature warehouses, particularly in food and pharmaceutical industries. It’s the optimal solution for storing of seasonal products in order to create buffer stocks.

Cargo vehicles enter deeply into racking Maximum warehouse space utilization (up to 80%). Use of drive-in/ drive-through racking saves significantly floor area of the storing facilities; low cost equipment compared with other high density storage technologies; Drive-in/ drive-through racking is designed for storing large volumes of similar products with a low turnover ratio; In one racking compartment can be stored only one SKU.

Mobile Pallet Racking

Advantages of mobile racking

- Increased storage capacity: movable storage racks provide 80 to 120% more storage capacity compared to conventional pallet racking.

- Direct access: this is the only high-density storage system allowing direct access to all stock stored.

- Cold storage energy savings: by making better use of space, the volume of air to be cooled is smaller, reducing energy consumption.

- Suitable for picking: with the multi-aisle operating mode, up to 3 aisles can be opened simultaneously (instead of just one) to perform picking.

- Versatility: mobile racking can be adapted to store non-palletised loads, such as coils, pipes and profiles.

- Scalable: the system adjusts to the growth of the warehouse. It can be expanded by adding additional mobile racking units.

- Safety and durability: the robust structure is equipped with numerous safety devices to protect operators and goods.

- High load capacity: each mobile base can move over 600 tonnes.

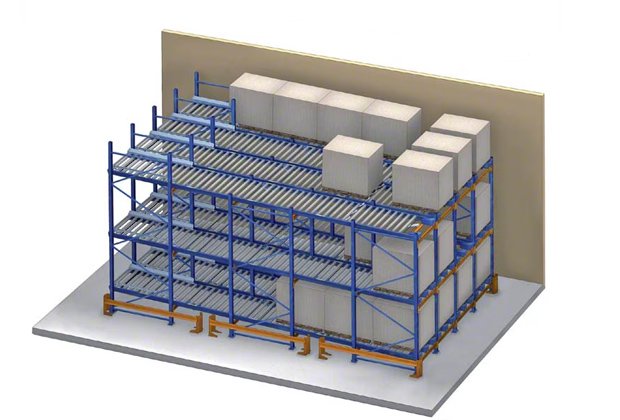

Pallet flow racking

Pallet flow racking consists of high-density storage structures formed by slightly sloped channels with rollers that enable pallets to slide into place. Palletised loads are inserted in the highest part of the channel and move by gravity to the opposite end, where they are ready to be removed.

There are no intermediate aisles in a flow rack system, which increases storage capacity. In addition, the flow through racking can work in line with the FIFO (first in, first out) strategy, facilitating efficient inventory management.

Advantages of pallet flow racking

- Maximum utilisation of surface area: pallet flow racking is a high-density storage solution that significantly increases a warehouse’s capacity.

- Flawless product turnover: its compatibility with the FIFO method fosters excellent inventory control.

- Time savings: having all SKUs available in a single working aisle makes it easy to locate any product, reducing forklift manoeuvring time and speeding up pallet removal.

- Separation of loading and unloading: pallet storage and retrieval are performed from separate aisles. This eliminates interference and enables forklifts to work without interruptions.

- Multiple SKUs: although each channel houses a single SKU, these can vary between the different channels.

- Better energy consumption: implementation of this system in facilities run at low temperatures reduces energy consumption since the volume to be cooled is smaller.

- Safety and reliability: the different elements that make up Mecalux’s pallet flow racks are designed to ensure risk-free operation for operators and goods.

Push-Back Pallet Racking

Push-back racking: storage by accumulation saves time and space

Push-back pallet racking is a high-density storage solution for housing several pallets deep with a different SKU in each channel. It works by accumulation: the load is pushed along rails mounted on a slight slope.

The push-back system is extremely agile. The forklift does not enter the racking, and goods are accessed from a single working aisle. This solution is based on the LIFO (last in, first out) goods management method.

Push-back racking advantages

- Space savings: doing away with intermediate aisles makes better use of the available surface area and increases storage capacity.

- Time gained: forklifts do not enter the racking, and operations are carried out from a single aisle. This significantly streamlines loading and unloading.

- Multiple SKUs: each storage channel can house a different SKU, making it possible to diversify the products stored.

- Low-to-high temperatures: the carts in the racking are prepared to work at temperatures ranging from -30 °C to 40 °C.

- Operational safety: the locking devices, stops, pallet centralisers, and other elements ensure safe and easy storage and retrieval manoeuvres.

- Low maintenance: the system requires very little maintenance, while its components ensure high strength and durability.

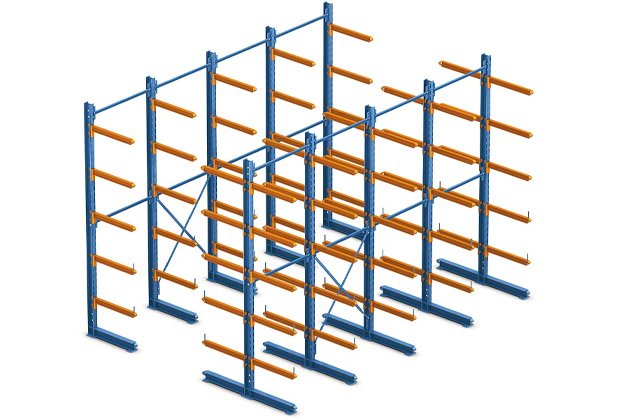

Cantilever racks

Cantilever racks are a medium to extra heavy-duty storage solution with load-bearing arms anchored to a steel column. These frames leave the front of the racks unimpeded by structural elements for direct pick access to goods.

As the optimal storage solution for lengthy or odd-shaped loads, cantilever racking easily holds furniture, lumber, tubes, fabric rolls, and pipes.

Available in both roll formed and structural steel designs, these cantilever rack systems are made for light duty to heavy duty applications.This multilevel storage system is designed and engineered to offer superior strength, stability and safety. All components are treated with a durable paint for a scratch-resistance finish and a matchless professional style.

Advantages

- Wide-ranging load capacities for standard or earthquake-resistant applications.

- Center column design creates unlimited horizontal space purposing.

- Adjustable 2-inch vertical arm spacing.

- Fully customizable

A broad array of custom designs and available accessories from Alkaswary mean these cantilever rack systems can handle the bulkiest storage requirements. Modules can also be mounted on mobile bases for increased storage capacity, without limiting direct access to each stored load.

Combine your cantilever racks with other storage systems, like pallet racks and light-duty pick shelves for a well-rounded omni-channel solution.