Cold Room Installation

Experts in the installation and maintenance of cold stores and cold rooms.

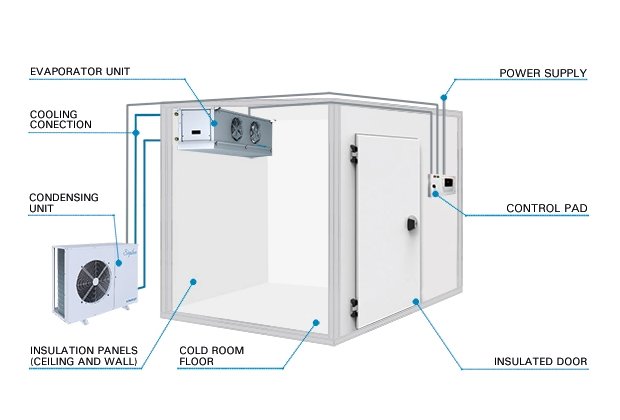

Cold room installation is a process that involves setting up a refrigerated space for storing or processing perishable goods. Cold rooms can vary in size, capacity, temperature, and refrigerant type depending on the application and customer requirements. Cold room installation requires careful planning, design, and execution to ensure optimal performance, safety, and compliance with regulations.

The cold room is comprised of two components, the refrigeration unit and the piping system. The refrigeration unit is the device that cools the air inside the cold room and maintains the desired temperature and humidity levels. It can be either a split type or a monoblock type, depending on the installation method and the refrigerant used. The piping system connects the refrigeration unit to the cold room and carries the refrigerant and the condensate. The piping system should be properly sized, insulated, and supported to prevent leaks, corrosion, or damage.

Cold and freezer room

Our engineers are experts in cold room installation, maintenance, and testing. After the installation is completed, the cold room should be tested and commissioned to ensure that it operates correctly and efficiently. The testing and commissioning process involves checking the refrigeration unit, the piping system, the electrical wiring, the monitoring system, and the cold room panels, doors, and accessories for any defects or errors. The process also involves adjusting the settings and calibrating the sensors and the control panel to achieve the optimal conditions for the cold room.

Cold room installation is a complex and specialized task that requires professional expertise and experience. If you are looking for a reliable and trustworthy partner for your cold room project, you can contact us for a free quotation. We have a wide range of products and solutions for cold rooms and walk-in refrigerators, and we can help you with the design, installation, and maintenance of your cold room.

Inverter Monoblock for Refrigeration

With Inverter monoblock, all the components of the refrigeration cycle, including the compressor, condenser, and evaporator, are housed in a single unit.

When it comes to cold rooms, there are several benefits to use this plug-and-play system, including:

Easy Installation: Inverter monoblock is easy to install compared to other refrigeration systems, which often require a separate compressor and condenser unit. This can result in faster installation times and lower installation costs.

Space Saving: Since all the components of the refrigeration system are housed in a single unit, LMS-Inverter monoblock takes up less space in the cold room. This can be especially beneficial for smaller cold rooms where space is limited.

Energy Efficiency: Inverter monoblock can be more energy-efficient than other refrigeration systems because it has fewer connections and less refrigerant piping, which reduces the risk of refrigerant leaks and energy losses.

Lower Maintenance: Inverter monoblock has fewer components than other refrigeration systems, which means there are fewer parts that can fail or require maintenance. This can result in lower maintenance costs and less downtime for your cold room.

Improved Performance: Inverter monoblock is designed to work optimally as a single unit, which can result in improved performance and better temperature control in the cold room